As outdoor living continues to grow in popularity, aluminum pergolas have become a preferred solution for homeowners and commercial spaces alike.

However, aluminum pergola pricing can vary significantly depending on various factors.

Understanding what influences pricing not only helps buyers set realistic budgets but also ensures they choose a pergola that performs well in their environment for years to come.

1. Size and Coverage Area

The overall dimensions of an aluminum pergola play a fundamental role in determining its price.

Total Square Footage

Larger pergolas require:

- More aluminum extrusions

- Additional roof components

- Increased hardware and fastening systems

- Longer installation time

As pergolas increase in size, structural demands also rise, which may require thicker beams or additional posts—driving costs beyond a simple linear calculation.

Span Length and Post Count

A pergola with wider, unsupported spans often needs reinforced beams or internal bracing. Designs that reduce the number of vertical posts for a cleaner aesthetic typically cost more due to the structural engineering involved.

Custom Shapes

Standard rectangular layouts are the most economical. L-shaped, trapezoidal, or curved pergolas require custom extrusion cutting and layout planning, increasing fabrication and labor costs.

2. Aluminum Frame Quality and Finish

Not all aluminum pergolas are created equal. The quality of aluminum materials significantly impacts pricing, durability, and safety.

Aluminum Alloy and Strength

High-quality pergolas typically use 6000-series aluminum alloys, known for:

- High tensile strength

- Corrosion resistance

- Excellent load-bearing capacity

Lower-grade aluminum may reduce upfront cost but can compromise longevity and structural stability.

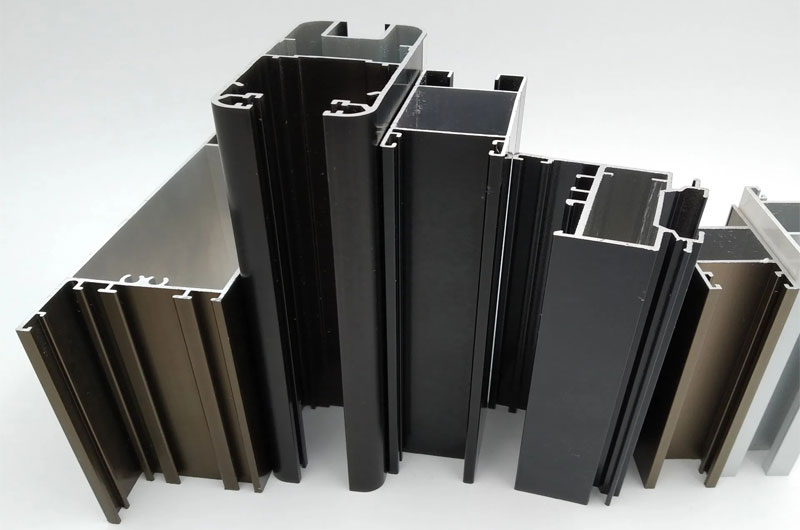

Wall Thickness of Extrusions

Thicker aluminum profiles:

- Support higher wind and snow loads

- Reduce vibration and movement

- Improve long-term performance

These benefits come with increased material usage and higher manufacturing costs.

Surface Treatments and Coatings

- Standard powder coating provides basic corrosion protection.

- Marine-grade powder coating is designed for coastal environments and adds cost.

- Wood-grain or custom color finishes require advanced coating processes and quality control.

Higher-end finishes improve aesthetics and lifespan but increase pricing accordingly.

3. Roof Types

The roof system is one of the largest cost variables in aluminum pergolas.

Open Pergola Roofs

Traditional open-beam pergolas provide partial shade and airflow. These options are typically the most budget-friendly, but they provide minimal protection from the elements.

Fixed Roof Systems

Fixed aluminum or insulated panel roofs:

- Provide full sun and rain protection

- Increase material weight and structural requirements

- Often require integrated drainage systems

Adjustable Louvered Roofs

Motorized or manual louvered roofs significantly increase cost due to:

- Precision-engineered moving components

- Drive systems and control mechanisms

- Weather sensors (rain, wind, snow)

While more expensive, adjustable roofs offer superior functionality and year-round usability.

4. Customization and Design Features

Customization enhances comfort and aesthetics but adds layers of cost.

Privacy and Weather Protection Add-Ons

Side zip screen blinds, sliding glass panels, or retractable shades increase material and installation costs while transforming the pergola into a semi-enclosed outdoor room.

Integrated Lighting Systems

Built-in LED lighting requires:

- Internal wiring channels

- Power supply integration

- Weatherproof electrical components

Smart lighting controls or color-changing systems further increase pricing.

Climate Comfort Accessories

Ceiling fans, infrared heaters, and misting systems improve usability but require:

- Electrical planning

- Structural support

- Additional installation time

5. Structural Reinforcement

Engineering considerations directly influence both safety and price.

Snow Load Capacity

In colder climates, pergolas must support accumulated snow weight, especially for fixed or louvered roofs. This often leads to:

- Heavier roof structures

- Additional support beams

Wind Load Ratings

Regions prone to high winds or hurricanes require:

- Thicker aluminum profiles

- Reinforced connections

- Stronger anchoring systems

Engineering Drawings and Certification

Some municipalities require stamped structural calculations. These professional services add design costs but ensure compliance and safety.

6. Installation Complexity and Labor

Installation costs can vary as much as material costs.

Site Conditions

Uneven terrain, existing landscaping, or sloped surfaces require additional groundwork such as leveling, concrete pouring, or reinforcement.

Foundation Requirements

Pergolas installed on:

- Concrete slabs are generally less expensive

- Pavers, decks, or soil may require custom footings or anchor plates

Electrical and Drainage Integration

Pergolas with lighting, motors, or drainage systems take longer to install and require skilled labor, increasing overall cost.

7. Geographic Location and Local Regulations

Where the pergola is installed matters.

Labor Rate Differences

Urban and high-cost-of-living areas generally have higher labor costs compared to rural regions.

Local Building Codes

Stricter codes can require:

- Additional permits

- Engineering documentation

- Inspections and compliance fees

Climate Considerations

Extreme climates influence design requirements, which directly affect pricing.

8. Brand, Manufacturer, and Warranty Coverage

The manufacturer behind the pergola can influence cost and long-term value.

Brand Reputation

Established aluminum pergola manufacturers often charge more due to:

- Proven quality control

- Better material sourcing

- Consistent design standards

Warranty Length and Coverage

Longer warranties typically indicate higher material and manufacturing standards. Transferable warranties also increase resale value.

After-Sales Support

Availability of replacement parts, technical support, and installation guidance can justify a higher upfront cost.

9. Market Conditions and Material Pricing

External economic factors also affect pergola pricing.

Aluminum Market Fluctuations

Global aluminum supply, tariffs, and energy costs can influence raw material prices.

Seasonal Demand

During peak outdoor construction seasons, labor rates tend to increase, and project timelines are often extended.

Transportation and Logistics

Larger pergolas require freight shipping, and fuel or logistics surcharges can impact final pricing.

10. Optional Upgrades That Enhance Long-Term Value

While optional, certain upgrades can significantly improve functionality.

Integrated Drainage Systems

Hidden gutters and downspouts improve water management and comfort during rain.

Smart Controls

Remote controls, smartphone apps, and automation systems increase convenience but add hardware and setup costs.

Design Integration

Matching pergola colors, finishes, or layouts to existing architecture may require custom fabrication.